Size of the entire paper industry is more than ₹80000 crores in India with a production of 25Mn tonnes per annum. Compared with the global level, India grabs around 5% paper market share. Above data is sourced from The Hindu BusinessLine.

Paper Manufacturers like you face many issues in improving the strength, printability and efficiency of your paper production. Due to high competition, every paper manufacturer needs to maintain high-quality standards with appropriate prices.

Here’s the secret ingredient that authorized paper manufacturers use i.e. Cellulose Powder (CMC powder or Carboxymethyl Cellulose).

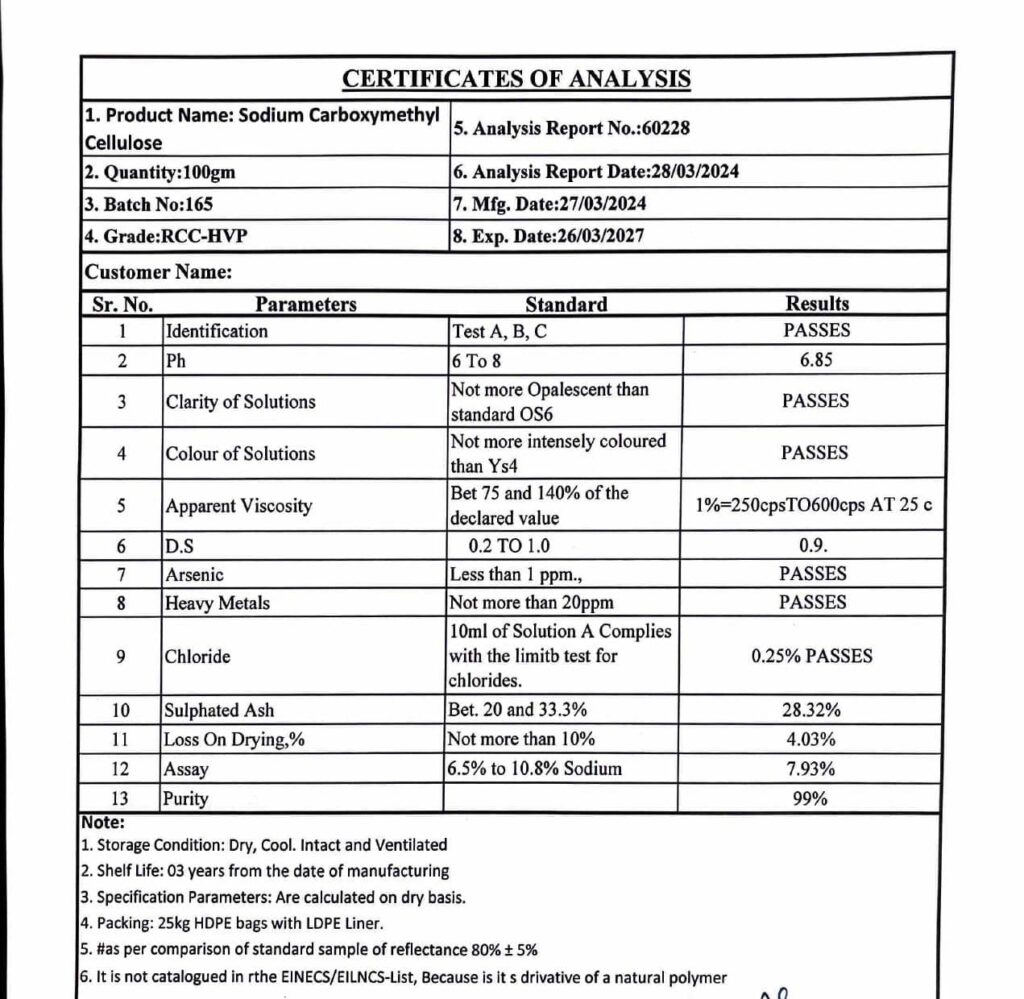

COA Report of CMC Powder for Paper Industry

CMC powder specifications and COA report is provided by Rashi Cellulose Chem, a cellulose manufacturing company in India.

Cellulose Powder Product List and Specifications

| Product Code | Viscosity in 1% solution (in Cps) | Purity |

| RCC – 10 | 40 to 220 Cps | 94% to 99% |

| RCC – 11 | 220 to 500 Cps | 94% to 99% |

| RCC – 12 | 500 to 2500 Cps | 94% to 99% |

CMC for Paper Industry COA Report [250 to 600 cps]

Benefits of CMC Powder for Paper Manufacturing

Cellulose powder for paper manufacturing comes with many advantages, here is the list.

- Increased Paper Strength: When you use CMC in paper production, you see an increased paper strength in both wet and dry conditions. It helps in reducing breakages and improved product quality.

- Improved Printability: Cellulose powder for paper manufacturing has helped in reduced ink absorption, more uniform paper surface, sharper prints in different colors and smoother final product.

- More Production: Cellulose powder helps in increased fiber dispersion, so your paper machines will work with fewer breaks and jams. So you can increase production speed by 5% to 20%. Eventually your production will increase at the same time as before.

- Better Moisture Retention: CMC powder helps in absorbing more moisture, it reduces curling and makes paper dimensionally stable.

- More Brighter Paper Production: Enhancement in paper’s surface properties lead to more brighter and visually appealing papers.

Adding cellulose powder while paper manufacturing is always an advantage. Rashi Cellulose Chem provides Cellulose powder for the paper industry in various different specifications.

Check the table below for better clarity.

| Features of Paper | Paper without CMC Powder | Paper with CMC Powder |

| Paper Strength (Dry) | Lower | Higher |

| Paper Strength (Wet) | Lower | Higher |

| Ink Absorption | Absorbs more ink | Absorbs less ink |

| Moisture & Water Retention | Lower | Higher |

| Production Speed | Normal Rate | Higher |

| Paper Machine Break & Jam | More Jamming | No breaks and jamming |

| Paper Smoothness | Less | More |

| Paper Curling | Paper curls | Paper doesn’t curl |

Applications of CMC Powder in Paper Industry

CMC powder is used in manufacturing of various paper grades like:

Major USPs of Rashi Cellulose Chem’s Cellulose Powder

Rashi Cellulose Chem manufactures CMC powder that helps you save more cost. Rashi Cellulose Chem’s CMC powder can be used in 2% solution and whereas other CMC powder in the market can’t be used in 2%. They can be used only above 4% solution.

So for example, if you use 10 kgs of CMC powder of other manufacturers, you only need to use 5 kgs of Rashi Cellulose Chem’s CMC powder. Eventually, you SAVE double the cost.

Contact us if you want to use Rashi Cellulose Chem’s product.

Want Cellulose Powder Sample for your Paper Manufacturing?

Adding CMC powder in your paper manufacturing process can help in increased paper quality, improved production speed and enhanced efficiency. Try out CMC powder in your manufacturing!

Contact Rashi Cellulose Chem for Cellulose Powder (CMC) Sample! Get it FREE at your address.